Our

Projects

Transfer of Crumb Rubber Modified Bitumen Technology to Western Australia

Project Overview

The practice of recycling end-of-life tyres for use in road construction has been in place for over 30 years in Western Australia.

Crumb rubber modified (CRM) binder technology can provide improved road performance, reduced landfill volumes and the preservation of natural resources, when applied to asphalts and sprayed bituminous seals.

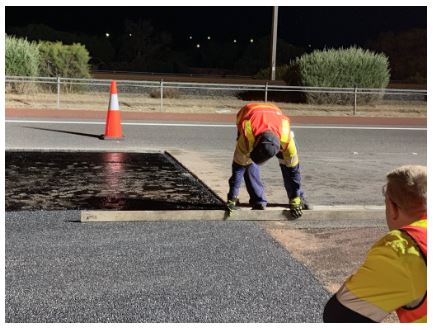

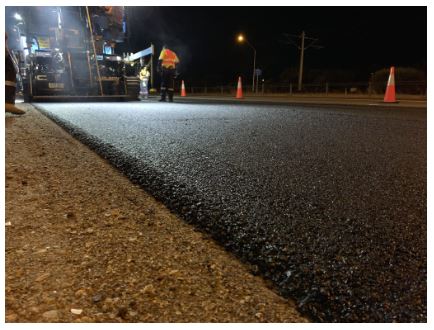

Over 3 stages, the development, implementation and characterisation of a CRM Open Graded Asphalt (OGA) and two CRM Gap Graded Asphalt (GGA) mixes for use in WA was realised through the WARRIP. Together with industry partner Fulton Hogan, these CRM asphalt mixes underwent manufacture and construction trials to evaluate the practicability of the mixes. Laboratory performance testing indicated that both mixes will perform well in the field, providing equal or greater durability when compared to the typical polymer modified binder mixes.

The results informed the development of draft specifications for CRM binder in both OGA and GGA mixes, facilitating use as a standard product in WA.

Contact Us

The Western Australian Road Research Innovation Program (WARRIP) is a collaborative research initiative between Main Roads Western Australia (Main Roads) and the Australian Road Research Board (ARRB).