Our

Projects

Investigating the use of Reclaimed Asphalt Pavement from Asphalt Containing Crumb Rubber Modified Binder

Project Overview

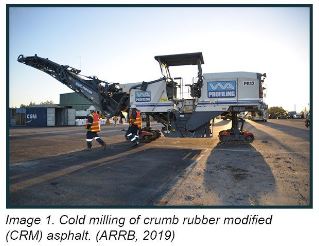

As new technology is trialled and rolled out there is a need to determine how recyclable these materials are. Crumb Rubber Modified (CRM) bitumen is gaining momentum and WARRIP is investigating the recyclability of asphalt containing CRM bitumen. To date the results have been promising, with further trials there should be a good guide as to the full potential to be realised.

Contact Us

The Western Australian Road Research Innovation Program (WARRIP) is a collaborative research initiative between Main Roads Western Australia (Main Roads) and the Australian Road Research Board (ARRB).